Effective Troubleshooting for Siemens S7-1200 and Allen-Bradley 1769 PLC I/O Modules

Estimated Reading Time: 7 minutes

- Understand common troubleshooting challenges for Siemens and Allen-Bradley PLCs.

- Learn effective diagnostic techniques and how to select compatible parts.

- Explore detailed troubleshooting steps for both systems.

- Review key differences between Siemens and Allen-Bradley technologies.

- Utilize FAQs to gain more insights into common issues.

Table of Contents

- An Overview of Troubleshooting Challenges for PLCs

- Common Challenges

- Selecting the Right Parts

- Siemens S7-1200 Troubleshooting

- Allen-Bradley 1769 Troubleshooting

- Power Supply and Configuration Checks

- Summary of Key Differences: Siemens vs. Allen-Bradley

- Practical Troubleshooting Workflow

- Conclusion

- FAQs

An Overview of Troubleshooting Challenges for PLCs

Troubleshooting Siemens S7-1200 and Allen-Bradley 1769 PLC I/O modules involves multiple facets: hardware checks, wiring inspections, and software analysis. These two systems are distinct in architecture, which influences how technicians approach fault finding and wiring checks. Here’s how you can tackle common issues effectively.

Common Challenges

- Physical Wiring Issues:

Loose connections or defective wiring can lead to major issues in both systems. It’s crucial to ensure that all I/O wiring is secure and properly terminated. - Module Recognition and Status:

Both platforms have their own methods for diagnosing module recognition problems, including module removals and communication faults.

Selecting the Right Parts

Having identified the issues, the next step is determining the correct replacement parts or accessories for your I/O modules. Here’s how to proceed.

Parts Selection Process

- Identify the Fault:

Use the diagnostic tools available for each system to determine the specific fault. For Siemens S7-1200, access TIA Portal to check for error messages. For Allen-Bradley 1769, reference the LED indicators on the modules. - Check Compatibility:

Ensure that the replacement parts you are considering are compatible with your existing PLC. Refer to manufacturer specifications and part number breakdowns. - Select Quality Components:

Choose components that adhere to industry standards for quality and reliability. It’s beneficial to source your parts from a reputable supplier. - Purchase Next Steps:

With parts identified, move on to the purchasing phase. Here, you can utilize our store, which features a wide range of industrial automation parts. You can browse our inventory directly online, making the ordering process more efficient.

Shop the Best Products for Your Needs

To streamline your selection, explore our dedicated categories for Siemens and Allen-Bradley parts:

Detailed Troubleshooting Steps

Siemens S7-1200 Troubleshooting

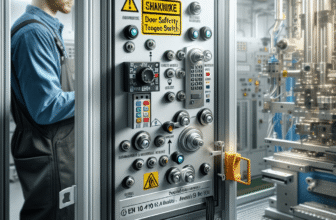

- Wiring and Physical Checks:

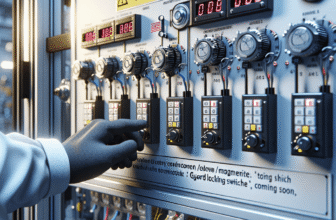

Start by ensuring all I/O wiring is secure and correctly terminated. Loose connections or wire breaks are significant causes of I/O faults (see Siemens Diagnostic Overview). Look over terminal blocks for proper installation and inspect for any signs of physical damage or corrosion. - Diagnostic Functions:

The Siemens S7-1200 utilizes a robust diagnostic system accessible through TIA Portal. This includes system messages like “Module removed” or “IO access error” that allow for fast identification of issues (refer to the diagnostic overview source). - Fault Diagnosis in Software:

Access fault information via the built-in web server or directly in TIA Portal. By enabling error events, you can analyze messages for any I/O errors. Follow these simple steps:

– Connect to the CPU using TIA Portal.

– Open online diagnostics.

– Review error logs for specific I/O messages. - Common Faults and Causes:

Be aware that faults can stem from various causes such as:

– Wire breaks

– Module detection issues

– PROFINET node errors

– Power supply malfunctions

– Incorrect software addressing (see resource for more details: Industrial Automation Blog).

Allen-Bradley 1769 Troubleshooting

- Wiring and Module Checks:

Ensure proper wiring and module seating within the chassis. Inspect connections in the backplane as these areas are often sources of errors. Use visual inspections and multimeters to confirm:

– Proper connections.

– Module integrity. - Diagnostic and Fault Handling:

Allen-Bradley PLCs come equipped with diagnostic LEDs that indicate module status and faults. Monitoring software like RSLogix 5000/Studio 5000 allows for on-the-fly diagnostics, helping to identify module-specific faults quickly. - Software Diagnostics:

Navigate to the Controller Organizer within your software, right-click on the relevant modules for diagnostics, and review the “Module Faults” field for detailed statuses of each component. - Common Faults and Causes:

Watch for issues that could arise from:

– Loose connections

– Defective modules

– Configuration errors

– Communication issues (refer to the comprehensive comparison of PLC hardware: DoSupply Tech).

Power Supply and Configuration Checks

- Power Supply:

Confirm all voltage levels are stable and meeting the specifications of both Siemens and Allen-Bradley systems. Unstable power can lead to intermittent faults. - Configuration Errors:

Check for configurations that may lead to “IO access errors” due to misconfigured module addresses (resource link: Industrial Automation Blog).

Summary of Key Differences: Siemens vs. Allen-Bradley

| Feature | Siemens S7-1200 | Allen-Bradley 1769 (CompactLogix) |

|---|---|---|

| Wiring Faults | Utilizes diagnostics for wire breaks | Status LEDs for diagnostics |

| Module Removal | Explicitly noted through TIA Portal | Detected via monitoring (RSLogix) |

| I/O Expansion | Limited to 8 signal modules | Scalable up to 31 modules |

| Remote I/O | Strong capabilities with ET200 | Limited flexibility in remote racks |

| Software Tools | Comprehensive TIA Portal | Intuitive Studio 5000 |

| Physical Diagnostics | Leveraging web diagnostics for in-depth analysis | Quick checks through module status LEDs |

Practical Troubleshooting Workflow

- Check Wiring and Connections:

Conduct thorough inspections and tests on cabling for continuity (watch a helpful guide here). - Inspect Status Indicators:

Review the LED indicators on the modules or dive into diagnostic buffers for Siemens. - Software Diagnostics:

Check error logs within TIA Portal or Studio 5000 for I/O communication errors and operational faults. - Power and Network Assurance:

Validate that stable power is being supplied and confirm the integrity of network configurations. - Replace Suspect Modules:

If errors persist post-troubleshooting, consider replacing hardware modules.

Conclusion

Both Siemens S7-1200 and Allen-Bradley 1769 (CompactLogix) systems have unique troubleshooting characteristics, each with specific diagnostic tools that can aid in identifying and rectifying faults.Partnering with an informed vendor ensures you have access to necessary parts while understanding the technical details can aid in ensuring smooth operations within your organization.

So, whether you’re in need of robust diagnostic tools or reliable I/O modules, our store is your go-to resource.

Free standard shipping available to US/CA/AU/UK (12-15 business days), with express options taking just 5-10 days. Check our Shipping Policy for more details.

14-day return window ensures you can shop with confidence—learn more in our Returns & Exchanges section.

FAQs

- What should I do if the I/O module is not recognized?

Ensure proper wiring and review module settings in your software. - How do I check the compatibility of new parts with my existing PLC?

Always review manufacturer specifications and compare part numbers before purchasing. - What is the average lead time for shipping my order?

Standard shipping typically takes 12-15 business days, while express shipping is 5-10 days. - Do you offer warranties on the products?

Most products come with a manufacturer’s warranty; please check individual product listings for details. - How should I install replacement modules?

Refer to the manufacturer’s installation guides and ensure all safety procedures are followed. - Can I get bulk pricing on parts?

Yes, simply reach out via our Contact Us page for specialized assistance on bulk orders.