Choosing Between Siemens SIMATIC HMI Panels and Allen-Bradley PanelView HMIs for Industrial Automation

Estimated reading time: 8 minutes

- Understanding the importance of choosing the right HMI

- Key considerations: integration, usability, durability, software

- Comparison of features and regional preferences

Table of Contents

- Introduction

- 1. Integration and Ecosystem

- 2. Ease of Use and Customization

- 3. Hardware Durability and Features

- 4. Software and Configuration

- 5. Support and Global Reach

- 6. Industry Preferences and Regional Trends

- Feature Comparison Table

- Expert Considerations for Selection

- Conclusion

- FAQ

Introduction

In the world of industrial automation, choosing the right human-machine interface (HMI) is crucial for optimizing efficiency and productivity in your facility. When comparing Siemens SIMATIC HMI Panels and Allen-Bradley PanelView HMIs, factors such as integration, usability, hardware durability, and regional preference play significant roles. This blog post will guide your decision-making process, helping you choose the best HMI for your needs.

1. Integration and Ecosystem

One of the first factors to consider when choosing between Siemens SIMATIC HMI and Allen-Bradley PanelView HMIs is how well each option integrates with your current systems.

- Siemens SIMATIC HMI is well integrated with Siemens PLCs and the TIA Portal engineering software. It supports a wide range of European industrial communication protocols such as PROFINET and PROFIBUS, making it a suitable option for facilities leveraging these systems.

- Allen-Bradley PanelView, on the other hand, excels within Rockwell’s Studio 5000 ecosystem. It is primarily designed to work seamlessly with Allen-Bradley PLCs using North American protocols like EtherNet/IP, DeviceNet, and ControlNet.

Choosing an HMI often depends on the existing control infrastructure in your plant. If you already utilize Siemens or Allen-Bradley PLCs, selecting the corresponding HMI will streamline engineering and maintenance tasks.

For a deeper exploration of our selection, visit the HMI category.

2. Ease of Use and Customization

Another essential comparison area is usability and customization.

- Allen-Bradley PanelView is known for its user-friendly interface, which has a lower learning curve. This attribute is particularly beneficial for technicians who may be new to automation, allowing them to quickly adapt and utilize the system for efficient operations.

- In contrast, Siemens SIMATIC HMI panels allow for greater customization and programming flexibility. This feature is ideal for applications requiring complex solutions or integration of advanced controls, although it does come with a steeper learning curve.

Consider your team’s experience and training when choosing an HMI. For operations requiring faster onboarding, PanelView would be more appropriate. In contrast, if your application necessitates advanced control capabilities, SIMATIC HMI would be the recommended choice.

Ready to enhance your operations? Check out Shop all parts today!

3. Hardware Durability and Features

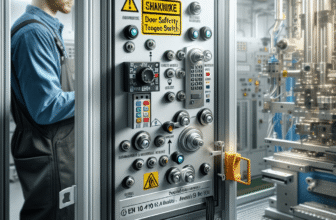

Durability is a crucial consideration when operating in harsh industrial environments.

- Both Siemens and Allen-Bradley offer rugged hardware designed to withstand temperature extremes, IP ingress protection, and vibration.

- Siemens panels typically feature built-in safety communication ports and support standard 24V DC supplies. In contrast, Allen-Bradley may require additional modules for similar functionality.

Ultimately, consider the specific environmental conditions within your facility and the potential need for rugged, durable equipment. When it comes to reliability and safety, Siemens systems often hold an edge with built-in features, while Allen-Bradley’s additional modules offer flexibility.

Explore the resilient options available in our Safety switches section for enhanced operational safety.

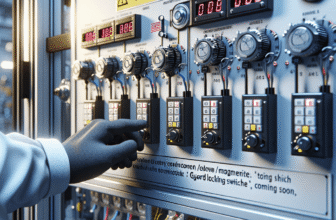

4. Software and Configuration

The software used to configure HMIs can greatly affect system performance.

- Siemens HMI panels are engineered through TIA Portal, enabling advanced diagnostics and seamless scalability across HMI and PLC product lines. A unified software platform can significantly reduce complexity in your automation strategy.

- Allen-Bradley’s HMI solutions, including FactoryTalk View Studio and Studio 5000, cater to different PanelView models (such as Plus, 5000, and 800). Each software tool is designed to address specific needs and levels of complexity for the respective PanelView models.

When selecting an HMI, consider the ease of software integration into existing processes. The more cohesive the software ecosystem, the more straightforward the implementation and troubleshooting become.

Take the first step toward efficient HMI configuration by checking out our selection in the HMI category.

5. Support and Global Reach

When it comes to technical support and spare parts availability, both Siemens and Allen-Bradley have a robust presence in their respective markets.

- Siemens provides 24/7 global technical support and is highly regarded for comprehensive spare parts availability, especially in Europe.

- Allen-Bradley also offers 24/7 support. Nevertheless, users may find that the depth of assistance provided can vary based on hardware volume, with a particularly strong service network in North America.

Consider evaluating your location and expected support needs when making your decision. For users in Europe, Siemens might offer a more viable support structure, while Allen-Bradley remains ideal in North American scenarios.

Ensure you understand our Shipping policy for seamless delivery of your industrial automation parts.

6. Industry Preferences and Regional Trends

Understanding regional trends can also aid in your decision-making process.

- Siemens is often viewed as the industry standard in Europe, aligning with preferred European engineering practices.

- Allen-Bradley, conversely, sees widespread adoption in North America, largely due to legacy installations and compliance with regional standards.

By factoring in your geographic location and industry standards, you can decide which HMI solution is the best fit for your facility. The alignment with regional trends often results in better integration with local systems and standards.

Feeling ready to make a decision? Don’t hesitate—Contact us for further assistance!

Feature Comparison Table:

| Feature | Siemens SIMATIC HMI | Allen-Bradley PanelView |

|---|---|---|

| Integration | Strong with TIA Portal, Siemens PLCs | Strong with Studio 5000, Rockwell PLCs |

| Protocols | European (PROFINET, PROFIBUS) | North American (Ethernet/IP, DeviceNet) |

| Customization | Highly customizable | User-friendly, less flexible |

| Hardware Installs | 24V DC supply, built-in safety | Module requirements may vary |

| Support | 24/7 global, extensive | 24/7, regionally strong |

| Industry Region | Europe | North America |

| Software | TIA Portal | FactoryTalk, Studio 5000 |

Expert Considerations for Selection

- Infrastructure Compatibility: If your plant’s automation infrastructure is already standardized on Siemens or Allen-Bradley PLCs, choose the matching HMI for tighter integration and simplified engineering.

- Team Training: For rapid deployment with novice technicians, PanelView provides easier onboarding, while SIMATIC HMI is preferable for advanced multi-system integration.

- Support Needs: Don’t forget to consider support requirements and spare part logistics. Evaluate the experience level of your maintenance teams to ensure proper handling of the chosen system.

Conclusion

Both Siemens SIMATIC HMI and Allen-Bradley PanelView are industry standards for a reason. Most factories select based on their existing control investments, team expertise, and required communication standards. Whether you prioritize integration, ease of use, customization, or support, a careful assessment of your operational needs will lead to the optimal choice for your facility.

As a part of our commitment to customer satisfaction, we offer free standard shipping to the US, CA, AU, and UK (12–15 business days), with express shipping options available (5–10 business days). Should you need to return an item, we provide a 14-day return window to ensure you have peace of mind with your purchases.

FAQ

- Q: What is the compatibility of Siemens SIMATIC HMI and Allen-Bradley PanelView with existing systems? A: Both HMIs integrate well with their respective PLCs: Siemens with TIA Portal and Allen-Bradley with Studio 5000. Compatibility depends on your existing infrastructure.

- Q: How long does it typically take to receive my HMI? A: We offer free standard shipping (12–15 business days) and express shipping (5–10 business days) to ensure prompt delivery.

- Q: Are there warranties on these products? A: Warranty information may vary by product; please check specific product details for warranty coverage.

- Q: Can novice technicians install these systems? A: Yes, the Allen-Bradley PanelView is designed for ease of use, making it suitable for those new to automation systems.

- Q: What kind of technical support is available? A: Siemens offers 24/7 global support, while Allen-Bradley also provides similar availability, especially strong in North America.

- Q: What should I do if I receive a defective product? A: You can utilize our 14-day return window policy to initiate returns or exchanges for defective items.

Don’t delay—improve your facility’s efficiency today by exploring our offerings and Shop all parts.