Understanding the Wiring Differences between Siemens 3RT and Allen‑Bradley 100‑C Contactors: An Essential Guide for Field Technicians

Estimated reading time: 5 minutes

- Key Differences: Siemens 3RT and Allen‑Bradley 100‑C contactors have distinct features that affect wiring.

- Part Selection: Knowing how to match parts is crucial for effective re-engineering during replacement.

- Wiring Basics: Familiarize yourself with wiring configurations specific to overload relays and contactors.

- Troubleshooting: Understanding common issues can save time during maintenance.

- FAQs: Address common concerns regarding compatibility and product selection.

Table of Contents

- 1. What “3RT vs 100‑C” Means for Your Wiring Needs

- 2. Key Factors When Cross-Replacing Contactors

- 3. Mechanical and Terminal Layout Differences

- 4. Wiring Basics for Overload Relays

- 5. Tips Specifically for Siemens 3RT + 3RU/3RB

- 6. Troubleshooting Scenarios for Siemens 3RT vs AB 100‑C

- 7. Design and Selection Tips

- 8. Practical Wiring Checklist

- Frequently Asked Questions (FAQs)

1. What “3RT vs 100‑C” Means for Your Wiring Needs

Siemens 3RT and Allen‑Bradley 100‑C are well-known contactor brands, each with unique characteristics. The Siemens 3RT is part of the SIRIUS IEC contactor line, handling a diverse range of power ratings from 3 to 500 A. Specifically, the 3RT family integrates thermal overload relays (3RU21) and electronic overloads (3RB3) to form comprehensive motor starters capable of handling various motor loads. On the other hand, Allen‑Bradley’s compact 100‑C series is designed to work with its overload relays, providing reliable performance in a compact design.

In mixed-panel setups, particularly when replacing an Allen‑Bradley 100‑C with a Siemens 3RT contactor, treating the situation as a re-engineering project is essential. You will need to match current/HP ratings, control logic, and the specific overload relay type rather than directly substituting components.

To shop for contactors and overload relays that suit your needs, visit our Shop this category.

2. Key Factors When Cross-Replacing Contactors

When swapping out an Allen‑Bradley 100‑C for a Siemens 3RT (or vice versa), there are several critical factors to consider:

a. Match Utilization Category and Current

Focus on AC‑3 current ratings to ensure compatibility for motor loads. For example, Siemens’ 3RT2046 (S2) is rated at 95 A AC‑3 and 75 HP @ 460 V.

b. Match Coil Voltage and Type

Ensure that the coil voltages are appropriately matched. Siemens 3RT contactors are available with AC, DC, or AC/DC coils depending on your requirements.

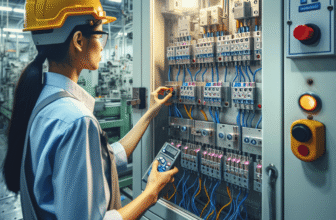

c. Overload Relay Selection

Overload relays need to be chosen according to the motor’s full-load amperage (FLA). Siemens overloads (3RU21/3RB3) and Allen-Bradley units (193-E) should fit the specified current ranges to ensure safe and efficient operation.

To ensure you are selecting the right parts, explore our Shopping category.

3. Mechanical and Terminal Layout Differences

The mechanical design and terminal arrangements of Siemens 3RT and Allen‑Bradley 100‑C are notably different.

Siemens 3RT Specifics

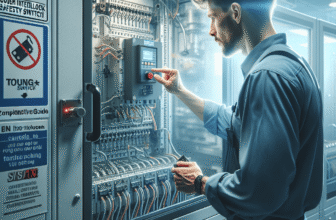

Siemens SIRIUS 3RT contactors have the main power terminals positioned at the top and bottom, with auxiliary contact blocks mountable on the sides or top. You’ll need to refer to Siemens catalogs for precise wiring layouts.

Allen‑Bradley 100‑C Specifics

The 100‑C series has a compact frame with its own specific terminal arrangements. AB documents provide clear terminal numbering and auxiliary contact configurations crucial for correct wiring.

Remember, always confirm wiring diagrams for any substitutions; don’t assume terminals are interchangeable. If you need high-quality products, check out our offers! Shop all parts.

4. Wiring Basics for Overload Relays

Understanding the wiring configuration for both Siemens and Allen‑Bradley systems involves:

Standard Wiring Path

The three-phase path generally follows: Line → Contactor main contacts → Overload relay → Motor.

The overload relay will include a normally closed (NC) trip contact wired into the control circuit to break the coil circuit upon overload.

Auxiliary Contacts

Expect to find both normally open (NO) and normally closed (NC) contact configurations for operational feedback and indicator purposes.

For reliable wiring choices, visit our Shop this category.

5. Tips Specifically for Siemens 3RT + 3RU/3RB

a. Choose the Right Overload Family

The Siemens catalog provides specific recommendations for using 3RU21 or 3RB3 overloads with respective 3RT contactors.

b. Check Link Modules

Siemens uses link modules (3RA19) to facilitate connections cleanly between contactors and motor protection circuit breakers.

c. Terminal Position Verification

Always refer to the internal diagrams for cross-checking terminal positions to troubleshoot effectively.

For more accessories to complement your setup, explore our collection. Shop this category.

6. Troubleshooting Scenarios for Siemens 3RT vs AB 100‑C

- Contactor Pulls In, Motor Will Not Start – Examine the wiring sequence ensuring power flows through all overloads and check for interruption paths.

- Overload Trips but Contactor Coil Stays Energized – Verify that the NC trip contact is correctly integrated into the coil circuit to cut off power when tripped.

- Replacing Overloads – Avoid interchanging overloads from different brands, as this could lead to operational inefficiencies and compliance issues.

- Coil Chatter or Overheating – This can generally occur from mismatched coil voltages—be sure the supply voltage matches the designated voltage for your contactor type.

For more detailed information or specific product inquiries, please Contact us.

7. Design and Selection Tips

Ecosystem Fit

Each brand’s ecosystem can significantly impact performance. Siemens integrates its 3RT series with SIRIUS accessories for a streamlined approach, while Allen‑Bradley’s 100‑C works smoothly with Rockwell PLCs.

Global Support

Both Siemens and Rockwell/AB offer robust support networks ensuring industry-standard compliance and reliability.

Cost Effectiveness

Users frequently note that Siemens products are often less costly than Allen‑Bradley without compromising performance or features.

To start your purchase journey or to learn more about our offerings, please visit Shop all parts.

8. Practical Wiring Checklist

Before installation, ensure:

- Proper orientation for line and load currents through both the contactor and overload relays.

- Verify motor full-load current aligns with the adjustable range of the overload relay.

- The NC trips are correctly placed in the control circuit.

- The auxiliary contacts used are suitable for the intended operation.

- Coil voltage matches the specifications: options range from 24 VDC to 240 VAC.

Ready to upgrade your industrial automation? Find quality products on our website. Shop all parts.

Frequently Asked Questions (FAQs)

- Q1: Can I mix Siemen 3RT with Allen‑Bradley overload relays?

A: It is generally not recommended; compatibility concerns exist regarding terminal arrangements and mechanical couplings. - Q2: What should I do if I have coil chatter after replacing contactors?

A: Check the coil voltage; ensure it matches the operational specifications necessary for the contactor type to pull in reliably. - Q3: Can I use the same overload relay for different brands?

A: Always verify, as most manufacturers recommend using matched models for optimal protection and reliability. - Q4: What is the lead time for shipping?

A: Enjoy free standard shipping on orders to the US, CA, AU, and UK within 12–15 business days, with express options available in 5–10 days see our shipping policy. - Q5: What’s the return window for products?

A: Our standard return policy allows for a 14-day return window for any items check here.

As you enhance your automation solutions with reliable contactors, feel free to browse our inventory to elevate your industrial operations. If you have questions or need further assistance, don’t hesitate to Contact us.