Siemens 3RT Contactors Wiring Issues Troubleshooting: A Comprehensive Guide for Industrial Automation Buyers

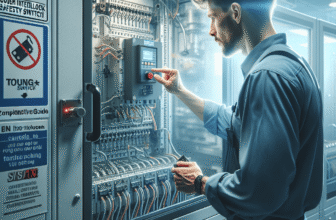

In the world of industrial automation, maintaining efficient and reliable operations is paramount. One critical component in many systems is the Siemens 3RT contactor. However, like any complex system, issues can arise, particularly in wiring. This guide will explore common wiring issues associated with Siemens 3RT contactors, how to troubleshoot them, parts selection for effective repairs, and purchase options for ensuring the smooth operation of your industrial automation systems. Whether you’re in Southeast Asia, the US, or a global enterprise, this article aims to provide practical insights to help maintenance teams and buyers navigate the complexities of Siemens contactors.

Understanding Siemens 3RT Contactors and Common Wiring Issues

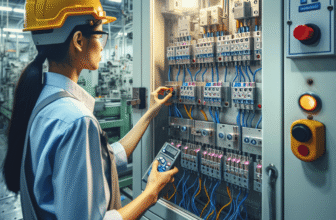

Siemens 3RT contactors are essential components in industrial automation, responsible for controlling the flow of electricity to various devices. These contactors utilize screw terminals, spring-loaded terminals, or busbar connections, depending on their size, which ranges from S00 to S12. Unfortunately, wiring issues can arise due to several factors, including incorrect conductor cross-sections, improper cable lug usage, and failure to maintain phase clearance.

Common Wiring Problems and Solutions

- Conductor Cross-Section Mismatches: Utilizing impractical conductor cross-sections can lead to poor contact and overheating. For example, when wiring the 3RT244 model, screw terminals with box terminals should be engaged as specified. Exceeding minimum conductor specifications may cause complications, so it’s essential to measure and adhere to the tables provided in the product manuals (Siemens Manual).

- Auxiliary/Control Circuit Issues: Wiring mistakes can also occur within auxiliary or control circuits, especially with larger control cables. Ensure your configuration aligns with the guidelines laid out in the product manual, especially sections that detail connection methods (Siemens Manual).

- Safety and Fail-Safe Wiring: For emergency stop or PLC-IN applications, make certain that you are using special versions of contactors designed for fail-safe inputs (Siemens Manual). Standard contactors require coupling links, such as the 3RH2924-1GP11 model.

- Installation Checks:

| Contactor Size/Type | Connection Type | Recommended Fix for Wiring Faults |

|---|---|---|

| 3RT2 (S00-S0) | Screw/spring main & auxiliary | Verify polarity for hoisting; test actuation. |

| 3RT2 (S2-S3) | Screw main; spring auxiliary | Replace coils if no actuation; check short-circuit protection. |

| 3RT14/145-147 (S6-S12) | Busbar/screw with lugs | Add box terminals or covers; RLT for vacuum interrupters. |

By identifying these wiring issues and understanding how to address them, maintenance teams can significantly reduce downtime and improve safety in industrial environments.

Next Steps and Parts Selection

After troubleshooting and identifying specific wiring issues, it’s time to select the right parts for replacements or enhancements. Here are some essential components to consider:

- Connecting elements: For proper connections, make sure to choose the right cable lugs, box terminals, or accessories like terminal covers (e.g., 3RT1956-4EA1 for >95 mm² conductors).

- Surge suppressors: Verify that AC/DC coils from version E03 incorporate integrated surge suppressors to prevent damage.

- Replacement Coils: If contactors are not actuating correctly, it may be necessary to replace solenoid coils (e.g., 3RT2.2 S0).

Consider the unique specifications of the contactors you are working with and cross-reference with the provided manuals for optimal selections.

Purchasing the Right Components

When you’re ready to purchase the necessary parts, visit our Shop this category for a comprehensive selection of Siemens 3RT contactors and related products. Remember, we offer free standard shipping to the US, CA, AU, and UK (12–15 business days) and express options (5–10 business days), ensuring that you receive your components quickly and efficiently.

Additionally, we maintain a straightforward 14-day return window for any unsuitable items purchased — refer to our returns page.

Testing and Maintenance Best Practices

Regular testing and maintenance are critical for the longevity of industrial components. For Siemens 3RT contactors, be sure to:

- Test continuity and insulation resistance regularly.

- Replace components like contact pieces or vacuum interrupters as specified in the manual (Siemens Manual).

- Use the video resources available for step-by-step guidance on testing and troubleshooting (View Video).

After ensuring all aspects are in order, you can confidently return to your operational routines.

Frequently Asked Questions (FAQ)

- What is the standard conductor cross-section for Siemens 3RT contactors?

The conductor cross-section must conform to manufacturer specifications outlined in the relevant manuals. Refer to the manuals for detailed tables. - Can Siemens 3RT contactors connect to Allen-Bradley 100-C overload relays?

While a direct reference is not available, ensure voltage and auxiliary contacts match specifications. Compatibility issues may arise from differing configurations. - What type of connection is recommended for 3RT contactors?

Depending on your contactor size, you may use screw terminals, spring-loaded terminals, or busbars. - How can I ensure the wiring is safe and compliant?

Adhere strictly to the wiring guidelines in the manuals and ensure that the components used are compliant with IEC standards. - What is the lead time for shipping parts?

Generally, we offer free standard shipping (12–15 business days) and express options (5–10 business days); check our shipping policy for more details. - What is your warranty on replacement parts?

Warranty specifics can vary—check individual product listings for details and terms applicable.

Conclusion

In conclusion, addressing Siemens 3RT contactors’ wiring issues requires attention to detail, understanding of common problems and solutions, and the right selection of parts for replacements. As you work through troubleshooting and component selection, consider our store for reliable options and strong policies to ensure seamless integration into your industrial automation needs. Start exploring effective solutions today by browsing our Shop all parts and enhance the efficiency of your operations.