Comprehensive Troubleshooting Guide for Siemens 3RT Contactors and Allen-Bradley 100-C Overload Relays

Estimated reading time: 8 minutes

- Understanding key wiring points and functionalities of Siemens 3RT contactors and Allen-Bradley 100-C overload relays.

- Step-by-step troubleshooting techniques to resolve common issues.

- Importance of parts selection for optimal performance.

- Effective maintenance practices to ensure longevity and efficiency.

- Resources for further information and support.

Table of Contents

- Understanding Siemens 3RT Contactors

- Troubleshooting Steps for Siemens 3RT Contactors

- Parts Selection for Siemens 3RT Contactors

- Understanding Allen-Bradley 100-C Overload Relays

- Troubleshooting Steps for Allen-Bradley 100-C Overload Relays

- Parts Selection for Allen-Bradley 100-C Overload Relays

- Conclusion: Selecting and Troubleshooting Your Automation Solutions

- FAQ Section

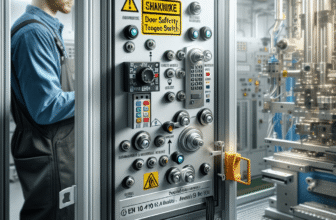

Understanding Siemens 3RT Contactors

Siemens 3RT contactors serve a critical function in industrial automation — they act as electromagnetic switches that allow remote control of power circuits, especially for motor operations. Understanding their services means understanding their key wiring points, troubleshooting steps, and potential faults.

Key Wiring Points for Siemens 3RT Contactors

- Main Circuit Terminals: Labeled L1, L2, L3 for the power supply and T1, T2, T3 for transitioning to the load or motor.

- Control Voltage Terminals: Usually labeled A1, A2 on the front, facilitating coil voltage connectivity.

- Auxiliary Contacts: Siemens 3RT contactors typically include one normally open (NO) and one normally closed (NC) auxiliary contact, which can be used for interlocking functions or feedback signals.

Wiring diagrams provided in Siemens documentation detail proper connection and interlocking, especially vital for standard and reversing circuits where misconnection could lead to operational failure (Siemens Manuals).

Troubleshooting Steps for Siemens 3RT Contactors

- Check Coil Voltage: Measure the voltage at terminals A1/A2 to ensure proper operation; absence indicates control supply issues.

- Inspect for Mechanical Interlock Failures: Check the reversing circuits for proper alignment of NC contacts.

- Tightness of Main Contacts: Ensure connections between L1-T1, L2-T2, L3-T3 are secure without overheating signs.

- Verify Auxiliary Contact Blocks: Miswiring could disrupt signal flow; ensure proper connections.

- Examine Wiring Quality: For spring-cage terminals, check for loose wires; screw terminals should be tightened completely.

- Reference Wiring Diagrams: Consult Siemens wiring guides to identify potential wiring errors.

Common Faults Include: Coil burnout due to incorrect voltage, mechanical jams, contact wear, and miswiring.

For complete details, visit the following resources: Shop this category, Shipping policy, Returns & exchanges, Contact us.

Parts Selection for Siemens 3RT Contactors

When selecting parts for your Siemens 3RT contactor, consider these essential components:

| Part Type | Part Number | Description |

|---|---|---|

| Siemens 3RT Contactor | 3RT1016-1BB4 | Basic contactor |

| Auxiliary Contact Block | 3RH1911-0BB4 | Used for feedback |

| Coil for Contactor | 3RT9037-1BB0 | Appropriate control voltage |

Choosing the correct Siemens parts ensures not only compliance but smooth operations in your control circuit.

Add to cart from the HMI category.

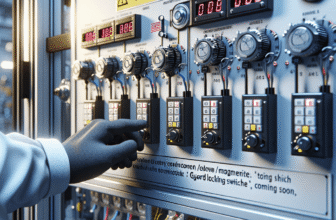

Understanding Allen-Bradley 100-C Overload Relays

Switching focus to motor protection, the Allen-Bradley 100-C overload relays are designed to provide safeguards against overloads and phase failures. Understanding their setup and functionality is vital for effective maintenance and troubleshooting.

Key Wiring Points for Allen-Bradley 100-C Overload Relays

- Power Connections: Power flows through L1-T1, L2-T2, and L3-T3, directly correlating with the motor.

- Control Terminals: Include trip indication and may connect to auxiliary contacts typically labeled 95, 96 for NC, and 97, 98 for NO functions.

Key Allen-Bradley literature illustrates the schematics for wiring integration (Rockwell Automation Documentation).

Troubleshooting Steps for Allen-Bradley 100-C Overload Relays

- Verify Current Setting: Ensure the overload is set accurate to the motor current rating.

- Confirm Wiring Integrity: Check for loose connections both at the relay’s main and auxiliary terminals.

- Test Trip and Reset Mechanism: Manually engage trip/reset to test functionality post a trip event.

- Phase Check: Ensure that all three phases are operational, as an open phase may cause tripping.

- Review Wiring Diagrams: To confirm correct integration with the contactor, prevent miswiring.

Common Faults Include: Incorrectly set currents, phase imbalances, and miswired auxiliary feedback.

For complete details, visit the following resources: Shop this category, Shipping policy, Returns & exchanges, Contact us.

Parts Selection for Allen-Bradley 100-C Overload Relays

For effective protection solutions, select the right parts from Allen-Bradley:

| Part Type | Part Number | Description |

|---|---|---|

| Allen-Bradley 100-C Relay | 100-C12N215 | Overload relay |

| Auxiliary Contacts | 100-C95A1 | NO Auxiliary contacts |

| Bimetallic Overload Sensor | 100-C24-A | Phase failure detection |

Choosing the correct overload relay ensures robust protection against motor damage.

Add to cart from the HMI category.

Conclusion: Selecting and Troubleshooting Your Automation Solutions

Understanding the intertwined roles of Siemens 3RT contactors and Allen-Bradley 100-C overload relays is crucial for maintaining effective industrial automation systems. A solid foundation in their operation, wiring configurations, and common faults empowers maintenance teams to troubleshoot issues efficiently.

FAQ Section

- What is the compatibility of Siemens 3RT contactors with other brands? While they are designed to be integrated within Siemens systems, they can work with third-party components providing voltage and current specifications align.

- How long is the lead time for delivery? Our standard shipping time is 12-15 business days, with express options available within 5-10 days. Check our Shipping policy for details.

- What warranty is included with these products? Most of our products come with manufacturer warranties. However, specifics can vary, so please refer to product details on our site.

- Are installation tips available for these components? Yes, you can find installation guides in their respective manuals linked throughout this guide, or contact us for further assistance.

- What is the return process if the part does not fit? We offer a 14-day return window as per our Returns & exchanges policy.

- How should I maintain my Siemens and Allen-Bradley components? Regular inspections of wiring, terminal connections, and feedback circuits will help maintain equipment efficiency and longevity.

For detailed troubleshooting, always consult the manufacturer’s wiring diagrams and installation manuals. Ensure proper installation to maximize performance and compliance for all your automation needs.