Selecting the Right Human-Machine Interface (HMI) for Industrial Automation

Estimated reading time: 5 minutes

- Understanding the importance of selecting the right HMI for optimizing operations.

- Key factors include environmental suitability, compatibility, and user interface design.

- Comparative analysis of Allen-Bradley and Siemens HMI solutions.

- Assessing operating environments, temperature requirements, and protection standards.

- Evaluating advanced features and connectivity for future scalability.

Table of Contents

- Understanding HMI Selection Fundamentals

- Operating Environment Assessment

- Allen-Bradley PanelView Selection Guide

- Siemens HMI Integration

- Advanced HMI Features and Capabilities

- Data Processing and Connectivity Requirements

- Conclusion

- Frequently Asked Questions

Understanding HMI Selection Fundamentals

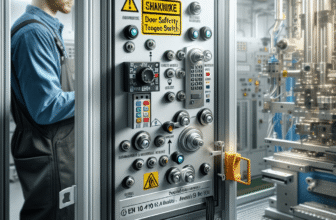

The primary function of an HMI is to connect and communicate with various devices in an industrial setup. Modern industrial HMI panels serve as the interface between human operators and automated systems, making it essential to consider environmental conditions, communication protocols, and system integration requirements. Key factors include:

- Environmental Suitability: Temperature ranges, humidity levels, and exposure to dust or chemicals greatly influence the HMI’s performance and longevity.

- Compatibility: Ensuring the HMI aligns with existing systems and devices is imperative for smooth operation.

- User-Friendly Interface: A straightforward interface enhances user experience and reduces the training time required for staff.

Understanding these fundamentals will assist you in making informed purchasing decisions and selecting suitable parts for your operations.

Add to cart from the HMI category.

Operating Environment Assessment

When selecting an HMI, assessing the operating environment is a definitive step. Various environmental factors can influence the performance and reliability of your HMI, ultimately affecting the efficiency of your operations.

Temperature Considerations

For factories operating in extreme environments exposed to wide temperature variations, selecting HMIs with the appropriate operating temperature range is essential. Industrial-grade HMI solutions typically support ranges from -20°C to 60°C (-4°F to 140°F) to accommodate diverse applications and environments (source).

| HMI Model | Operating Temperature Range |

|---|---|

| Siemens S7 | -20°C to 60°C |

| Allen-Bradley PanelView Plus 7 | -20°C to 60°C |

| Red Lion HMI | -40°C to 70°C |

Protection Requirements

In industries such as food and beverage manufacturing and pharmaceuticals, hygiene and cleanliness standards are paramount. Therefore, waterproof HMIs with high Ingress Protection (IP) ratings are essential. For hazardous environments, HMIs with explosion-proof certifications like C1D2 and ATEX are necessary.

| Protection Level | Description |

|---|---|

| IP65 | Dust-tight; protected against water jets |

| IP67 | Dust-tight; withstands immersion in water up to 1 meter |

| C1D2 & ATEX | Suitable for hazardous locations (explosion-proof) |

By conducting a thorough assessment of operating environment requirements, you ensure that the chosen HMI maintains performance standards.

Explore suitable options in the HMI category.

Allen-Bradley PanelView Selection Guide

Allen-Bradley offers a range of HMI solutions tailored to suit various application requirements. There are two primary series to consider: the PanelView Plus 7 and the PanelView 800.

PanelView Plus 7 Series

The PanelView Plus 7 series includes Standard and Performance models designed for different levels of functionality.

| Feature | Standard Model | Performance Model |

|---|---|---|

| Memory | 512 MB RAM | 1GB RAM |

| Display Sizes | 4″ to 12″ | 7″ to 19″ |

| Ethernet Ports | Single | Dual |

| VNC Server | Basic | Advanced |

The PanelView Plus 7 Performance model is ideal for applications demanding advanced functionality and enhanced connectivity options.

PanelView 800 Series

Designed for compact spaces, the PanelView 800 series integrates effortlessly with Micro 800 controllers, making it ideal for general-purpose motor control applications.

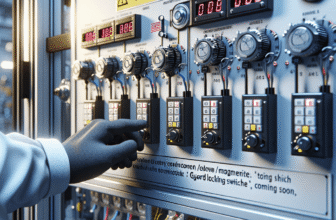

Allen-Bradley Communication Protocols

Allen-Bradley HMIs support various PLC brands, including ControlLogix, CompactLogix, Micro8xx, and MicroLogix. Key communication options include:

- EtherNet/IP: For Compact/ControlLogix/DriveLogix connections.

- DF1: For serial communications with SLC500 and MicroLogix series.

- DH485: Point-to-point communications.

When choosing an Allen-Bradley HMI, analyze your communication needs to ensure it can easily integrate with existing systems.

Purchase your Allen-Bradley HMI from the HMI category.

Siemens HMI Integration

Siemens offers a robust range of HMIs compatible with various PLC series.

Compatible PLC Series

Siemens HMIs support the S7-1200/1500, LOGO, S5 Series, and other Siemens PLC brands such as S7-200/300/400.

Communication Setup Requirements

Proper communication cable configurations are crucial for connecting Siemens HMIs with the SIMATIC S7-200/S7-400 PLCs. The S7-1200/1500 series allows Ethernet connectivity, offering both symbolic addressing (recommended for newer installations) and absolute addressing for legacy system compatibility.

With Siemens HMIs, ensure you have the correct setup to facilitate smooth communication and integration with existing systems.

Browse Siemens options in the HMI category.

Advanced HMI Features and Capabilities

When choosing an HMI solution, it is essential to evaluate advanced features offered by various manufacturers. One notable alternative is Red Lion’s HMI solutions.

Red Lion HMI Solutions

Red Lion provides rugged, flexible HMI panels suitable for challenging environments. Key features include:

- Multiple serial ports

- USB Host capability

- Ethernet connectivity

- C-Type User Programming

- Protocol Converter functionality

These features make Red Lion HMIs ideal for diverse applications, including factory automation, oil and gas, and water/wastewater management (source).

Software Integration

Modern HMI systems require seamless integration with software solutions such as FactoryTalk View and Studio 5000. These integrations enhance the user experience and allow for comprehensive system configuration.

Shop for advanced HMI options in the HMI category.

Data Processing and Connectivity Requirements

When selecting an HMI, consider additional factors such as data processing capabilities, connectivity, expandability, and flexibility. Evaluating these elements ensures that your chosen HMI can handle current demands while providing scalability for future needs.

Proper HMI selection enhances the visualization of raw data, allows for more efficient operations, and supports edge computing, ultimately driving productivity in various industrial applications.

Ensure connectivity with high-quality parts from our HMI category.

Conclusion

In conclusion, selecting the right HMI for industrial automation is a multifaceted decision that requires careful consideration of various factors—from environmental conditions to system compatibility and advanced features. By following the outlined assessment procedures, you can make informed decisions that optimize performance and productivity in your operations.

Frequently Asked Questions

1. What types of industrial environments can HMIs operate in?

HMIs can operate in a variety of environments, but specific models are designed for extreme conditions. Look for models with wide temperature ranges and IP ratings for moisture and dust protection.

2. Are Allen-Bradley HMIs compatible with Siemens PLCs?

No, Allen-Bradley HMIs are primarily designed to work with Allen-Bradley PLCs. If you are using Siemens PLCs, it is advisable to choose Siemens HMIs for better compatibility and performance.

3. What is the lead time for HMI deliveries?

Lead times can vary based on stock availability and shipping methods. We offer free standard shipping to the US, Canada, Australia, and the UK (12–15 business days), with express options available (5–10 business days) – see our Shipping policy for more information.

4. Is there a warranty on the HMI products?

Most HMI products come with a manufacturer warranty. Please refer to the respective product information for detailed warranty conditions.

5. Can I return or exchange the purchased HMI?

Yes, we offer a 14-day return window for purchases. Please check our Returns & exchanges page for more details.

6. How can I contact you for bulk pricing or other inquiries?

Feel free to reach out with any questions or requests for bulk pricing via our Contact us page.

Investing time in selecting the right HMI will ultimately result in enhanced operational efficiency and a more productive workplace. Start exploring our HMI category to find the best options for your facility today!