Choosing the Right HMI: A Comprehensive Guide for Industrial Automation

Estimated reading time: 5 minutes

- Understand your application needs.

- Assess environmental conditions for reliability.

- Identify display and interface requirements.

- Evaluate computing and memory needs.

- Ensure connectivity and protocol support.

Table of Contents

- Understanding Your HMI Needs

- Identifying Application Demands

- Assessing Environmental Conditions

- Display and Interface Requirements

- Determining Computing & Memory Needs

- Connectivity and Protocol Support

- Driver Support and Maintenance Checklist

- Summary of Best Practices

- Frequently Asked Questions (FAQs)

Understanding Your HMI Needs

Identifying Application Demands

Choosing the right HMI begins with understanding your application needs. The core requirements often fall into several categories:

- Machine Control: A basic requirement for operation and management of machinery.

- Data Visualization: Visual displays to interpret real-time data effectively.

- Data Logging: Recording data points for historical analysis and reporting.

- Recipe Management: Storing and retrieving production recipes for consistency.

- SCADA-level Oversight: Involves supervisory control and data acquisition for extensive monitoring.

Identifying which of these applications is crucial for your operation will significantly influence your HMI selection process. Vendors provide various models suited for specific applications, making it essential to align your expectations with the capabilities of the chosen device. For more detailed insights, refer to the sources from Advantech and AutomationDirect.

Transactional CTA: Explore options in our HMI category today!

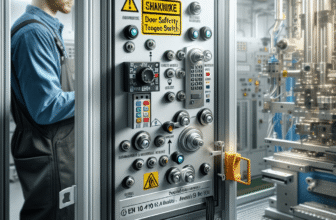

Assessing Environmental Conditions

Next, consider the environmental factors that will affect your HMI. HMIs are used in diverse conditions, and assessing these factors upfront helps ensure reliability:

- Temperature Range: Ensure the HMI operates within the specific temperature thresholds of your environment.

- Dust and Vibration: Applications in dusty or high-vibration settings necessitate ruggedized HMIs.

- Water Ingress: IP ratings (Ingress Protection) specify resistance to water and dust—critical for outdoor or wash-down applications.

- Hazardous Locations: An explosion-proof HMI may be required for specific industries, such as petrochemicals.

Choosing an HMI with the appropriate certifications for your operating conditions is essential for preventing equipment failure and ensuring safety in the workplace. For additional details, visit sources like Advantech.

Transactional CTA: Make sure your HMI can handle your environment. Check our HMI category now!

Display and Interface Requirements

The display is one of the most critical components of an HMI. Selecting the right type involves several considerations:

- Display Size: Choose a size appropriate for visibility across your workspace.

- Touchscreen Type: Capacitive touchscreens are more sensitive and suitable for cleanroom environments, while resistive screens allow usage with gloves.

- Readability: Ensure your HMI is readable in the lighting conditions of your environment, which can include direct sunlight.

Identifying these requirements will aid in narrowing down your options to HMIs that enhance user interaction without compromising functionality. Details on display and interface needs can be found on AutomationDirect.

Transactional CTA: Find the perfect display for your operations in our HMI category!

Determining Computing & Memory Needs

Understanding your HMI’s computing and memory needs is crucial for sustained operations. You must evaluate:

- Tag Counts: The number of data points your HMI will handle.

- Graphics Complexity: Complex graphics require more processing power and memory.

- Storage Required for Scripts/Recipes: Determine if substantial memory is necessary for processes.

By estimating these components, you can choose an HMI that not only meets your current needs but also offers scalability for future growth. For more insights related to these elements, see AutomationDirect.

Transactional CTA: Ensure your HMI has the power and memory for your needs. Shop now in the HMI category!

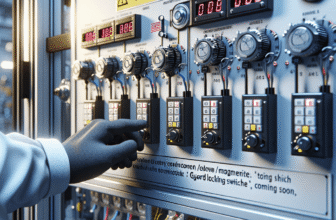

Connectivity and Protocol Support

Connectivity is another critical aspect to evaluate. Depending on your existing infrastructure, consider the following:

- Protocol Support: Ensure compatibility with PLCs and communication protocols—addressing needs for Siemens S7, Allen-Bradley EtherNet/IP, or Schneider Modbus.

- Connectivity Options: Consider options like Ethernet, USB, HDMI, or serial ports that may be required for integration.

These specifications will determine how well the HMI can communicate with other devices in your system. Refer to Maple Systems for a comprehensive overview.

Here’s a vendor compatibility table to help clarify:

| Vendor | Typical HMI Series | Key PLC Protocols | Notable Software | Compatibility Notes |

|---|---|---|---|---|

| Siemens | SIMATIC HMI Comfort, Basic, Mobile | S7 (MPI, Profibus, Profinet) | WinCC | Best compatibility with Siemens S7 PLCs; check TIA Portal version for newer panels. |

| Allen-Bradley | PanelView Plus, PanelView 5310/5510 | EtherNet/IP, DF1, DH+ | FactoryTalk View | Designed for seamless use with Logix/CompactLogix/ControlLogix PLCs; verify firmware and ADI driver for required PLC family. |

| Schneider Electric | Magelis (Harmony), HMIST6, HMIGTO | Modbus, Ethernet/IP, CANopen | Vijeo Designer | Strong compatibility with Modicon PLCs; also supports 3rd party PLCs—review protocol licensing and driver set. |

Transactional CTA: Confirm compatibility with your controllers by visiting our HMI category!

Driver Support and Maintenance Checklist

Make sure the support for drivers aligns with your specific PLC or motor drives. Verify the availability of drivers for your hardware and ensure they are compatible with the firmware version of your devices. Regular maintenance is also essential to keep your HMI operating smoothly:

- Routine Inspections: Check for physical issues or display problems.

- Connection Health: Regularly inspect connectors to maintain optimal communication.

- Software Updates: Keep firmware up to date to address vulnerabilities and improve functionality.

- Environment Cleaning: Maintain cleanliness of the unit according to manufacturer recommendations.

For further details on maintaining the longevity of your HMI, see Advantech.

Transactional CTA: Check out our HMI category to find the perfect solution for your maintenance needs!

Summary of Best Practices

When identifying an HMI, it’s important to consider various factors. Using the right vendor tools, like Siemens TIA Portal or Schneider Vijeo Designer, for configuration ensures correct setup and deployment. Cross-platform considerations can aid in integrating different devices, but optimal performance is achieved with devices from the same vendor.

To wrap it up, when choosing an HMI, balance functionality with compatibility and ongoing support. Ensure you choose a device that matches both your current and future automation requirements for seamless integration and sustained performance.

Transactional CTA: Browse our entire selection of HMIs available in our HMI category!

Frequently Asked Questions (FAQs)

1. What should I consider for HMI compatibility?

When choosing an HMI, ensure that it supports the protocols of your existing PLCs and integration standards. Compatibility with both the manufacturer’s tools and drivers is crucial.

2. What is the lead time for HMIs?

Lead times can vary based on model availability and shipping location. For standard shipping to the US, Canada, Australia, and the UK, expect delivery in 12-15 business days. Check our shipping policy for more information.

3. Does your store offer a warranty on HMIs?

Yes, we offer a warranty for our HMIs. Check product details for specific terms, and feel free to reach out for further clarification.

4. Can I install the HMI myself?

Most HMIs come with user manuals that provide installation guidelines. For complex systems involving significant wiring or programming, it’s advised to consult with a qualified technician.

5. What is the return policy for HMIs?

We have a 14-day return window for all products, including HMIs. For more information, please refer to our returns & exchanges policy.

6. How do I maintain my HMI?

Regular routine inspections, updates for firmware/software, and environmental cleaning based on the manufacturer’s directions will significantly prolong the life of your HMI.

By understanding the essential criteria for HMI selection, you can effectively choose the right part for your industrial automation needs. For further assistance or specialized inquiries, do not hesitate to Contact us. Start optimizing your operations with the right HMI today!