Brand Comparison for HMI Selection: Finding the Best Fit for Your Industrial Automation Needs

Estimated Reading Time: 8 minutes

- Understand key compatibility issues in HMI selection.

- Evaluate user interface needs for efficient operation.

- Compare leading HMI brands: Siemens, Allen-Bradley, Schneider Electric.

- Follow structured purchasing steps for informed decisions.

- Consider future growth and vendor support in your selection.

Table of Contents

- Understanding the Need for HMI

- Common Problems in HMI Selection

- The Path from Problem Identification to Parts Selection

- Part Selection: HMI Brand Comparison

- Siemens HMI

- Allen-Bradley HMI

- Schneider Electric HMI

- Purchasing Steps

- Wiring Tips for Successful Installation

- Additional Considerations

- Frequently Asked Questions (FAQ)

- Conclusion

Understanding the Need for HMI

In the realm of industrial automation, the HMI serves as the critical point of interaction between operators and machines. A well-chosen HMI can dramatically enhance system efficiency, operator engagement, and ultimately, productivity. However, the selection process can be complicated by the number of available features and the compatibility of various components.

Common Problems in HMI Selection

- Compatibility Issues: Choosing an HMI that aligns with existing controllers and protocols is essential. Mismatched devices can lead to communication failures and operational downtime.

- User Interface Needs: The interface must be intuitive enough for users to operate efficiently. Difficult-to-navigate systems can cause frustration and operational delays.

- Standards Compliance: Different regions have varied compliance requirements impacting HMI acceptance in specific applications, particularly in power and utility industries.

The Path from Problem Identification to Parts Selection

Identifying the need for a new HMI typically stems from issues related to operational efficiency or technological advancements. Here’s how to move from problem identification to effective parts selection:

- Assessing System Compatibility: Evaluate your existing systems to ensure that any new HMI supports relevant communication protocols such as Profinet, Profibus, Ethernet/IP, and Modbus.

- Defining User Interface Needs: Engage your team to understand their requirements. For example, if ease of use is paramount, Allen-Bradley HMIs are often preferred for their user-friendliness.

- Compliance and Standards: Factor in regional standards—particularly if operating in regions with stringent requirements, such as Europe—when deciding on your HMI.

Understanding your operational environment facilitates clear choices when selecting from available HMI options within your budget and required specifications.

Part Selection: HMI Brand Comparison

To assist in selecting the right HMI, the following comparison offers insights into the primary features of our leading brands.

| Feature | Siemens | Allen-Bradley (Rockwell) | Schneider Electric |

|---|---|---|---|

| Preferred Region | Europe, global | North America, global | Europe, global |

| Primary Protocols | Profinet, Profibus, OPC UA | Ethernet/IP, DeviceNet, DH+ | Modbus, Ethernet/IP, CANOpen |

| Software | TIA Portal, WinCC | Studio 5000, FactoryTalk | EcoStruxure Operator Terminal |

| Ease of Use | Advanced, less intuitive | Very user-friendly | Moderate, web-based options |

| Customizability | Extensive, high-end | Moderate, tag-based | Good, with modular options |

| Common Use Cases | Large, complex, demanding | Factory/OEM, mid-large scale | OEMs, utilities, general |

Siemens HMI

Siemens HMIs often cater to complex applications, especially in industries requiring advanced integration, such as manufacturing and processing plants. Their systems are widely used in Europe, allowing for deep customization with the support of protocols like Profinet and Profibus.

User Considerations

- Use Case: Ideal for multinational operations and projects requiring robust customization.

- Software: TIA Portal offers detailed configuration tools, but may pose a learning curve for new users.

If you’re handling advanced operations requiring top-tier integration capabilities, consider HMI category offerings from Siemens.

Allen-Bradley HMI

Renowned for their user-friendly interfaces, Allen-Bradley HMIs are extensively adopted in North America, particularly in OEM and factory settings. Their systems work seamlessly with Rockwell Automation’s ControlLogix line.

User Considerations

- Use Case: Suitable for developers needing rapid deployment and straightforward maintenance.

- Software: Studio 5000 is optimized for ease of use and swift integration.

For straightforward operational needs, explore our offerings in the HMI category today.

Schneider Electric HMI

Schneider Electric’s offer in HMIs, such as the Magelis series, emphasizes versatility and compatibility with diverse applications and protocols.

User Considerations

- Use Case: Excellent for utility applications requiring reliable and interoperable systems.

- Software: EcoStruxure Operator Terminal boasts broad support across various PLCs.

Discover if Schneider Electric HMIs fit your project needs by visiting the HMI category.

Purchasing Steps

Once you’ve narrowed down your choices, it’s essential to follow these steps to simplify the purchasing process:

- Confirm Compatibility: Review the specifications of your chosen HMI against your PLC’s communication protocols.

- Select Accessories: Consider additional components such as I/O modules if you need to expand functionality.

- Review Store Policies: Familiarize yourself with shipping and return policies to ensure flexibility in your purchase.

Important Policies:

- Free standard shipping is applied to US/CA/AU/UK orders (12–15 business days).

- Express shipping is available (5–10 business days).

- A 14-day return window allows for adjustments if the selected parts don’t meet your needs.

Add to your cart from the HMI category and take advantage of our shipping and return policies.

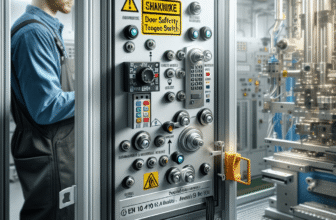

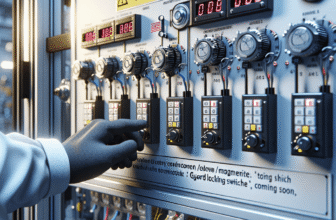

Wiring Tips for Successful Installation

To ensure your HMI operates smoothly, follow these installation tips:

- Power Requirements: Confirm the voltage requirements for your selected HMI—most Siemens and Schneider HMIs run on 24V DC, while Allen-Bradley may require different inputs based on the model.

- Grounding/Shielding: Ground the HMI as per the manufacturer’s instructions to reduce electrical noise risk. In environments with high interference, use shielded cables.

- Networking: Utilize the appropriate cabling for communication, e.g., Ethernet for digital communication and RS-232 for serial connections.

- Panel Layout: Keep HMIs away from heat sources or high-voltage areas to prolong their lifespan.

Planning for wiring and installation correctly can prevent future issues. If you’re ready to purchase, visit the HMI category for a selection of quality HMIs.

Additional Considerations

A successful HMI integration won’t just stop at initial selection. Consider future growth, security, and vendor support:

- Future Expansion: Plan for expected growth in I/O needs and screen additions. An HMI with scalable features can save time and cost in the future.

- Security: Ensure that your selected HMI provides adequate user authentication and cybersecurity features as per your industry standards.

- Vendor Support: Investigate the supplier’s documentation, update mechanisms, and tech support availability—critical for ongoing operations.

Keep these considerations in mind and browse for your HMI needs in the HMI category.

Frequently Asked Questions (FAQ)

- Q1: What factors should I consider for compatibility?

- A1: Ensure the HMI supports the communication protocol used by your PLC (e.g., Profinet, Ethernet/IP) and consider potential cross-brand communications.

- Q2: How long will shipping take for my HMI order?

- A2: We offer free standard shipping to US/CA/AU/UK orders that typically takes 12-15 business days. You can also choose express shipping, which ranges from 5-10 business days.

- Q3: Is there a warranty on the HMIs sold?

- A3: Yes, most HMIs come with a standard warranty covering defects. For specifics, consult the manufacturer’s warranty policy.

- Q4: How do I handle installation if I’m unfamiliar with HMIs?

- A4: It’s recommended to follow the manufacturer’s wiring and installation guidelines closely. Consult technical manuals or reach out to our support team for assistance.

- Q5: What if the HMI doesn’t meet my expectations?

- A5: We offer a 14-day return window if the purchased item does not meet your needs. Check our returns page for more details.

- Q6: Can I request bulk pricing for HMIs?

- A6: Yes! If you’re considering bulk purchases, reach out for pricing and quotes through our Contact us page.

Conclusion

Choosing the right HMI can significantly impact operational efficiency and user experience in your industrial automation processes. By understanding the differences between Siemens, Allen-Bradley, and Schneider Electric HMIs, aligning your selection with your needs, and following the outlined purchasing steps, you can simplify your selection process and enhance your operational setup. For your next HMI project, be sure to explore our offerings in the HMI category and enjoy the support we provide through our policies.

Thank you for considering us for your industrial automation needs; we look forward to serving you.